Grandly held from June 19 to 21 at the Shenzhen World Exhibition & Convention Center (Bao'an), the 2024 South China International Industrial Fair, brought together over 800 leading domestic and international enterprises. It featured a diverse range of cutting-edge technologies, products, and solutions spanning the intelligent industrial supply chain.

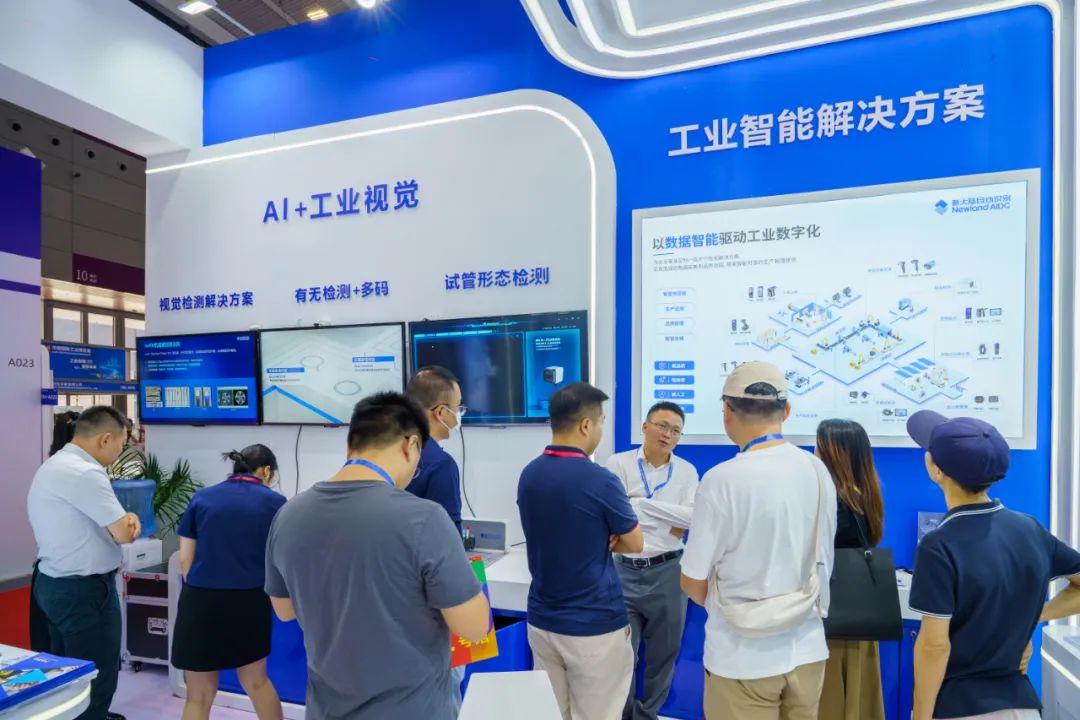

Newland AIDC, a global provider of perception & identification and machine vision products and solutions, participated under the theme "AI Drives Industrial Manufacturing to 'New' Heights." The Company presented its comprehensive suite of industrial digital intelligence management solutions and the latest product applications, highlighting a new ecosystem for industrial perception & identification applications in the AI+ era, which drew significant interest from industry representatives and experts, who stopped by to learn more about its offerings.

As global informatization and intelligentization accelerate, automation and artificial intelligence have become indispensable drivers of new quality productive forces. The "AI+" technology is ushering in a new era of intelligence in manufacturing. Newland AIDC closely integrates user needs into its technological innovations, continuously advancing the application of AI+ machine vision technology. So the Company's showcase of AI-powered solutions drew significant attention at this year's fair.

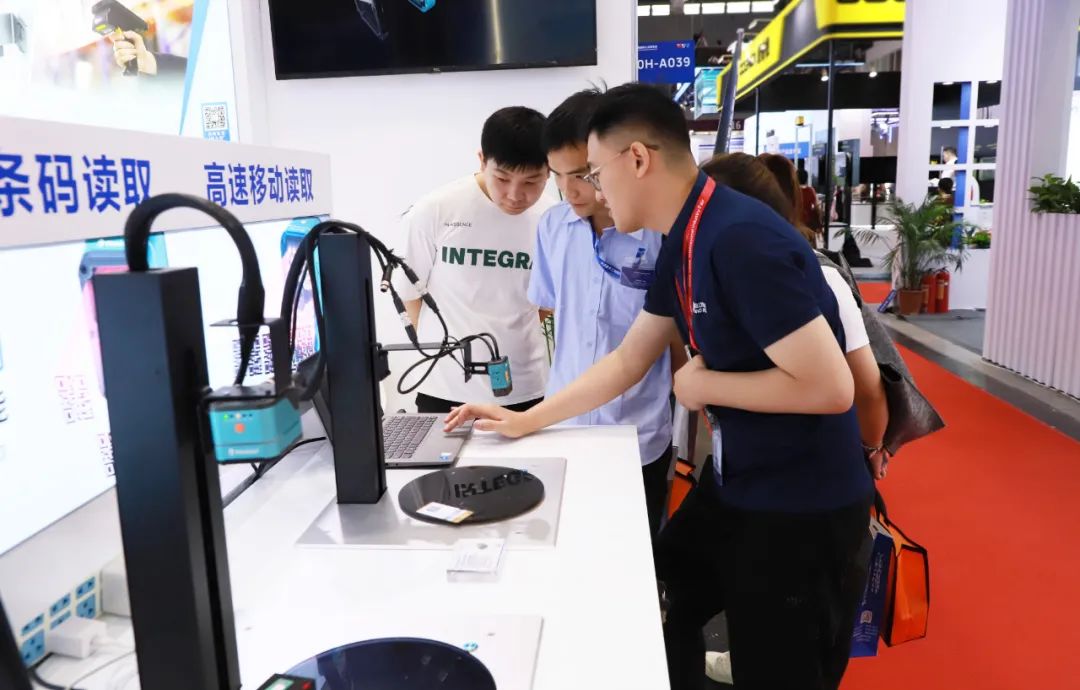

The Newland Soldier300 series industrial smart scanners are equipped with a new generation of decoding algorithms and AI smart algorithms, delivering superior computational power to meet the demands of rapid image acquisition and efficient decoding, with the single-image decoding speed doubling compared to previous models. Additionally, the scanners are equipped with a built-in multi-channel lighting system that accommodates a diverse range of lighting accessories. Combined with a high-speed liquid autofocus lens and a one-button tuning function, the scanners can automatically adapt to different code reading scenarios, allowing for reliable barcode reading at various working distances and fields of view, making them suitable for applications with large fields of view and deep depths of field, and ultimately improving data collection efficiency.

Tailored to the general requirements of industrial scenarios, the Newland NVH220 series industrial portable barcode scanners are equipped with AI cores to enable intelligent scene recognition and automatic scene switching, offering flexible operation and ease of use. Trained on hundreds of thousands of images, these scanners can efficiently decode challenging barcodes, including those that are reflective, low-contrast, curved, damaged, densely packed, or distorted. This achievement significantly enhances the decoding success rate, making the NVH220 series a reliable choice for universal industrial applications.

Newland's latest generation of Soldier180 industrial fixed mount scanners are powered by AI, greatly enhancing their recognition capabilities and compatibility in complex scenarios. The incorporation of industrial Ethernet simplifies user accessibility, leading to production lines that are more flexible, precise, and efficient.

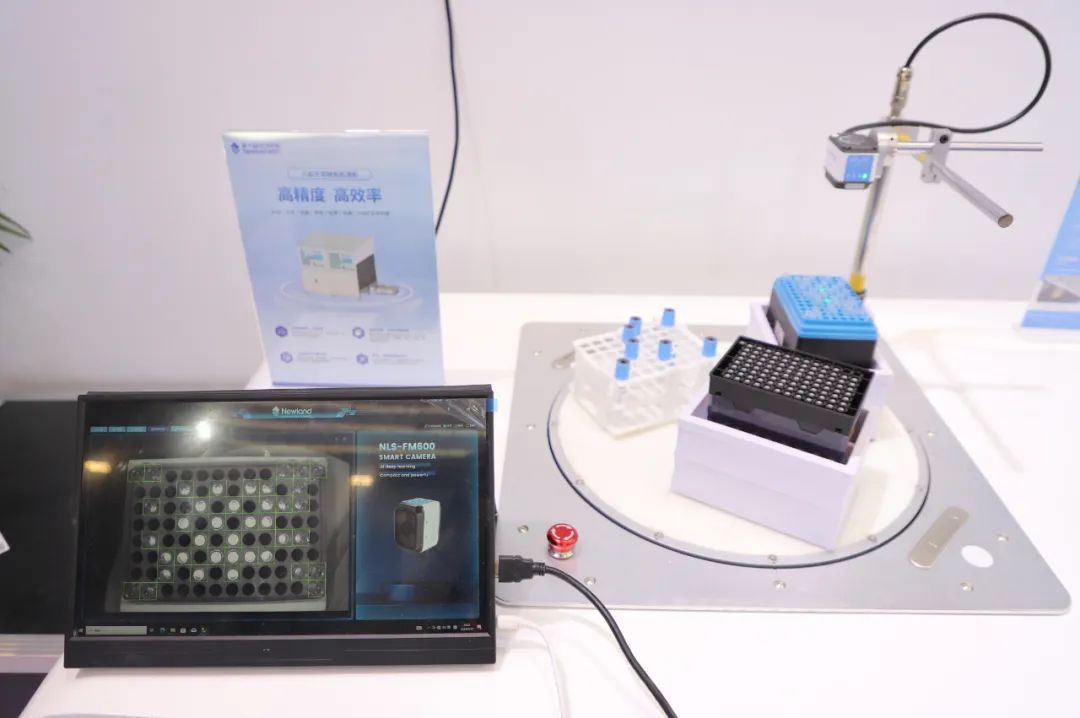

In the realm of AI+ industrial vision, Newland's self-developed nvKit machine vision operator library excels in applications such as detection, measurement, identification, and positioning guidance, finding widespread use across various projects. The Newland FM600 smart camera, equipped with a high-performance AI deep learning platform, combines traditional vision algorithms with AI algorithms. This function delivers exceptional accuracy with only a limited number of sample images for training, providing robust support for diverse and complex scenarios such as presence detection, shape classification, OCR, and multiple code reading. Furthermore, Newland’s vision inspection solutions offer customized solutions based on functionality dimensions such as high-speed, high-precision detection, quick target recognition, and support for diverse content inspection, which drives the intelligent upgrade of industries such as new energy, 3C electronics, automotive, pharmaceuticals, and food.

Looking ahead, the widespread adoption of AI technologies will drive deeper integration of products with specific business scenarios, achieving higher levels of intelligence, sparking a wave of innovations and transformations in industrial manufacturing, and rejuvenating the sector with new vitality.

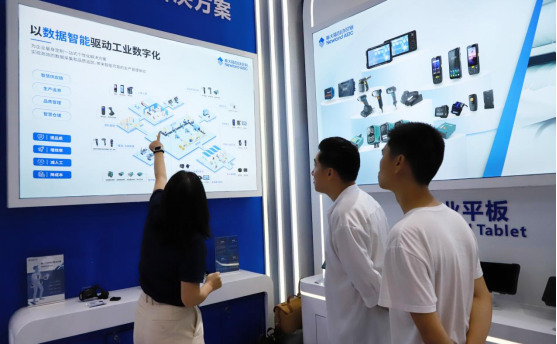

With smart manufacturing and digital transformation rapidly advancing, the application of machine vision in industrial settings is becoming increasingly prevalent. Newland AIDC, by integrating barcode recognition, RFID, and machine vision technologies, leverages the advantages of "AI+" to comprehensively upgrade its technology and enhance the ability of its products to compete domestically and internationally as an alternative. Meanwhile, on the application level, the Company provides users with more flexible and systematic digital intelligence management solutions, effectively overcoming challenges in various typical application scenarios.

Newland's industrial digital intelligence management solutions cover all stages of the production process, from raw materials and semi-finished products, to finished products, including transport, warehousing, and distribution, enabling more reliable data collection and quality management, more convenient and transparent traceability, more direct process monitoring, smarter production control, and more precise full lifecycle product management. These solutions have already been extensively adopted across various industries, including 3C electronics, new energy, automotive manufacturing, pharmaceuticals and food, warehousing and logistics, and steel manufacturing, among others.

For example, in 3C electronics manufacturing, Newland achieves rapid multi-scenario switching through versatile product combinations, covering over 20 processes from material preparation to in-and-out warehousing, significantly enhancing the production efficiency of factory lines. In lithium battery production, the Company offers solutions for process traceability and quality management across more than 50 procedures in the early, middle, and late stages, meeting the demand for domestic alternatives and the high requirements for efficiency, precision, and traceability. In photovoltaic manufacturing, Newland's algorithm-based barcode correction capabilities allow for the reconstruction of high-density barcodes affected by deformation and grainy noise, effectively addressing issues of irregular textures and module distortions. In automotive manufacturing, Newland starts with imaging and algorithms, using a multi-channel lighting system to tackle complex automotive part barcode decoding. This involves creating specialized algorithms and integrating image preprocessing functions, ensuring its products are perfectly adapted to the complex scenarios in car manufacturing.

As a key promoter of industrial intelligence transformation, Newland AIDC will continue to focus on research and innovation in AI+ machine vision technology, helping manufacturing enterprises achieve automated production. Simultaneously, Newland will foster industry collaboration and exchanges within the industry, jointly exploring the application and development opportunities of "AI+" across a wider range of fields and collectively advancing the sustained development of industrial intelligence.

Search

Search

专业的顾问服务

专业的顾问服务